09/30/2016. Remarks by

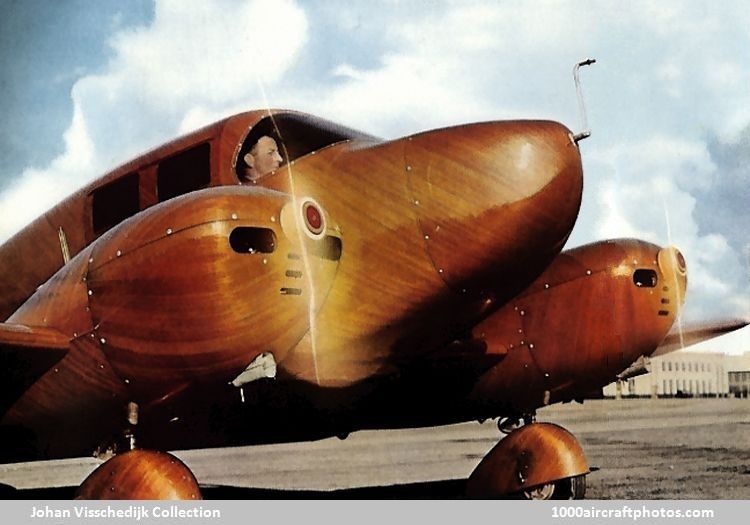

Johan Visschedijk: "The Langley Aircraft Corporation in Port Washington, New York was formed in 1941 to exploit the new Vidal patented process of molded plastic plywood construction to form most components of an aircraft. This to avoid wartime strategic materials. Sections of the aircraft were integrally molded from multiple layers of Honduras mahogany veneer placed over each other while dry on wooden molds and permanently bonded together by plastic composition under heat and pressure. Hence the aircraft was also referred to as a plastic plane, as shown in a February 16, 1942 advertisement by the plastic composition

manufacturer.

The streamlined model 2-4-65 (initially designated simply Langley Monoplane) was designed by Martin Jensen, assisted by Arthur Draper. The pictured first prototype was powered by two 65 hp Franklin engines.

Langley 2-4-65 (NX29099) (

Johan Visschedijk Collection)

To emphasize its wood construction it was finished in clear varnish, hence it was also called "an exquisite piece of furniture". Registered NX29099, it was first flown in 1941.

As the aircraft was underpowered the second Langley Monoplane prototype was initially fitted with two 75 hp engines which soon were replaced by two 90 hp engines. This prototype was designated 2-4-90 and was first flown in 1942. Subsequently it was purchased by the USN under the designation XNL-1 and BuNo. 39056.

The Langley Aircraft Corporation received the CAA Type Certificate Number 755 for the model 2-4-90 on December 29, 1943. In the previous year Langley had been acquired by the Andover-Kent Aviation Company at New Brunswick, New Jersey and the latter company planned to produce the type in series. Ironically, by the time of certification the plastic compositions were no longer available as they became strategic materials and the project was ended. Reports that examples were produced after WW II are not supported by known allotted registrations.

Langley 2-4-90 (N51076) (

Ed Coates Memorial Collection)

The XNL-1 was sold as war surplus and it came on the civil register as NC51076, on January 1, 1949, the "C" was dropped from the registration. On September 26, 1965, the aircraft ground-looped upon landing at Tulsa, Oklahoma, USA and the fuselage was damaged beyond economical repair. Subsequently the undamaged wings and engines were used to build the

Pierce Arrow."

The following data is from 1942.

Type: Four-seat cabin monoplane.

Wings: Low-wing cantilever monoplane in five sections, comprising rectangular center section, two tapering outer and two semi-circular wing tips. Ailerons on outer tapering sections.

Fuselage: Molded plastic plywood structure in three sections, comprising a nose-piece and two longitudinal halves joined down the vertical center line.

Tail unit: Braced monoplane type with twin fins and rudders of molded plastic plywood construction. Single-piece elevator.

Landing gear: Fixed type. Consists of two cantilever shock-absorber legs with medium-pressure wheels carried in forks. Orientable tail wheel.

Power plant: Two 65 hp Franklin 4AC-176 (in 2-4-90 two 90 hp 4AC-199-E3) four-cylinder horizontally-opposed air-cooled engines in molded plastic plywood nacelles. Engine cowlings and fireproof bulkheads molded with an integral asbestos lining. Fuel tanks (40 gall, 151 l total capacity) in tails of engine nacelles behind fireproof bulkheads.

Accommodation: Enclosed cabin seating four in two pairs, the front pair having dual controls.

|

NOW FOR THE FIRST TIME

A PLASTIC PLANE . . .

thanks to a lump of coal

You've read in your newspaper recently about a new plane built almost entirely of plastic plywood and plastic parts.

A lump of coal supplies essential ingredients for many of the plastic used today in airplane construction – for wings, fuselages, fairings, radio antenna masts, trim tabs, control pulleys, pilot switch panels, cabin ventilators and cameras. Aircraft designers and builders are finding that plastics from coal offer priceless gifts in making stronger, better planes.

Coal derivatives help make plastics for hundreds of other everyday articles . . . pencils, clocks, raincoats, battery boxes, airconditioning grilles, radio cabinets, even table tops.

Chemicals from coal contribute to the American way of life too, by helping to give us everything from roads, pneumonia remedies, and weed killers to automobile tires, colorful clothes, clay pigeons, telephones and treated timbers.

It's no child's play to discover these hidden secrets of a lump of coal . . . to extract its chemical treasures and make them commercially available. But Koppers chemists have achieved some remarkable results. And they expect to achieve more in the months and years ahead. Maybe that's why the name of Koppers . . . the industry that serves all industry . . . is heard more and more often those days wherever you go.

|